10

2025

-

09

Hi-Tech Lecture Room | Misinstalled Hydraulic Hose Can Turn Into a Bomb! This "Explosion-Proofing Guide" for Hydraulic Hose Installation is a Must-Read!

Hydraulic Hose

Explosion-Proof Installation Guide

Amidst the roaring factory floor and humming machinery, seemingly insignificant hydraulic hoses are the lifeblood that keeps equipment pulsating. The efficient delivery of every drop of hydraulic fluid is crucial to production efficiency and operational safety. However, improper installation of these "blood vessels" can lead to leaks at best and even ruptures, causing serious accidents!

High-Tech Lecture Hall reveals key points in hydraulic hose installation, each of which is a solid guarantee for equipment stability and personnel safety!

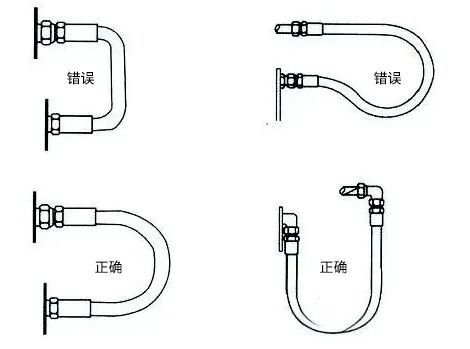

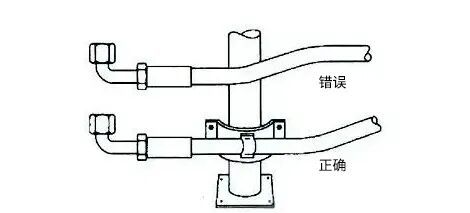

1. Avoid Twisting and Torsion

Prevent hydraulic hoses from twisting during installation! Tests have shown that twisting as little as 7° can reduce hose life by 80%. Precise installation and avoiding twisting are particularly crucial when connecting two components with relative motion or when the hose must bend in the same plane. Failure to do so will severely reduce the hose's pressure-bearing capacity and lifespan.

2. Allow Allowance

When installing the hose, allow a certain amount of allowance to accommodate expansion and contraction due to pressure fluctuations. It is generally recommended to leave a margin of approximately 3% to 5%.

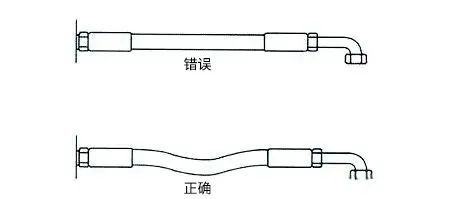

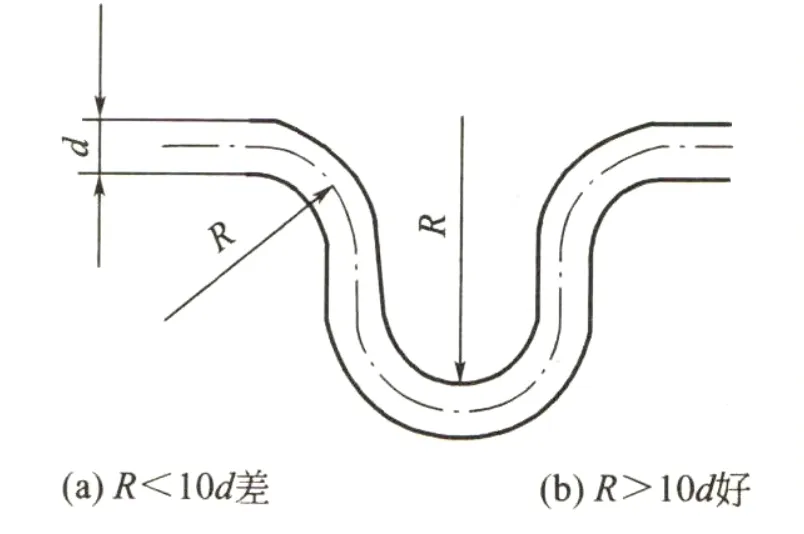

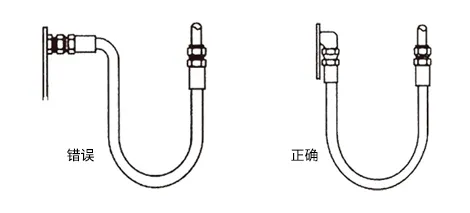

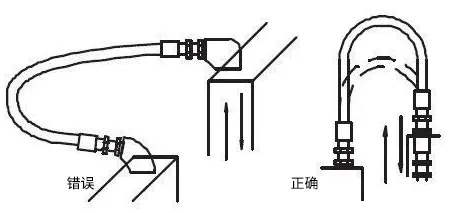

3. Meet Bend Radius Requirements

Overbending is strictly prohibited. The bend radius of the hose must not be less than 10 to 12 times its outer diameter to prevent collapse and deformation at the bend. Bends are strictly prohibited at the base of the hose connectors. A straight section with a length of 1.5 times the outer diameter must be maintained.

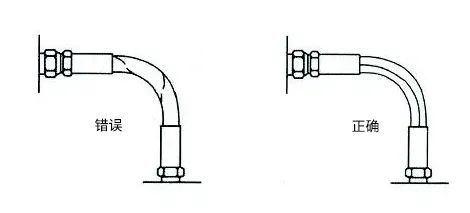

4. Correctly Determine Hose Length

Hose length should be selected based on its flexibility. Avoid hoses that are too long or too short. A hose that is too long will increase unnecessary costs, while a hose that is too short may rupture due to insufficient flexibility.

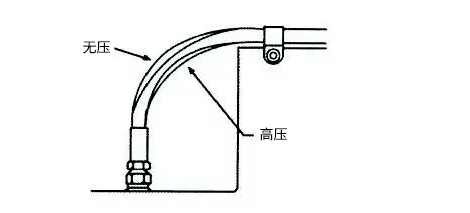

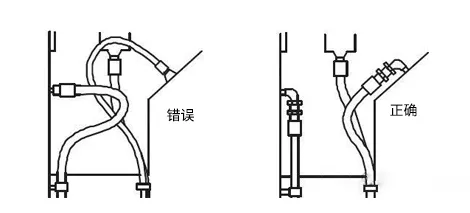

5. Precautions for Installing Pipe Clamps

When the hose is under pressure, do not install clamps where it bends; allow it to move freely. Install clamps on straight sections to ensure that the hose is not damaged by the clamps when under pressure.

6. Avoid Friction

Where possible, avoid direct contact between the hose and other objects or keep it away from other objects to reduce friction.

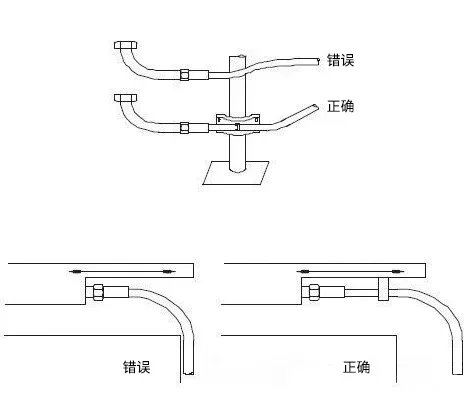

7. Choose the Right Connector

Use the right connector to maximize installation space and reduce unnecessary hose use.

Choose appropriate connectors to ensure the hose's bending plane aligns with the direction of movement to avoid twisting.

Use appropriate connectors to avoid excessively small bend radii to reduce additional stress.

8. Keep away from heat sources

Hydraulic hoses should be installed away from heat sources, such as diesel engine exhaust lines, to prevent aging or damage due to high temperatures.

Choose Gaoke Rubber & Plastics for professional protection! We not only provide high-quality, high-performance hydraulic hose products, but also advocate scientific and standardized installation and use.