11

2025

-

07

Growing Demand for Steel Wire Braided Hydraulic Hoses Highlights Importance of Quality and Maintenance

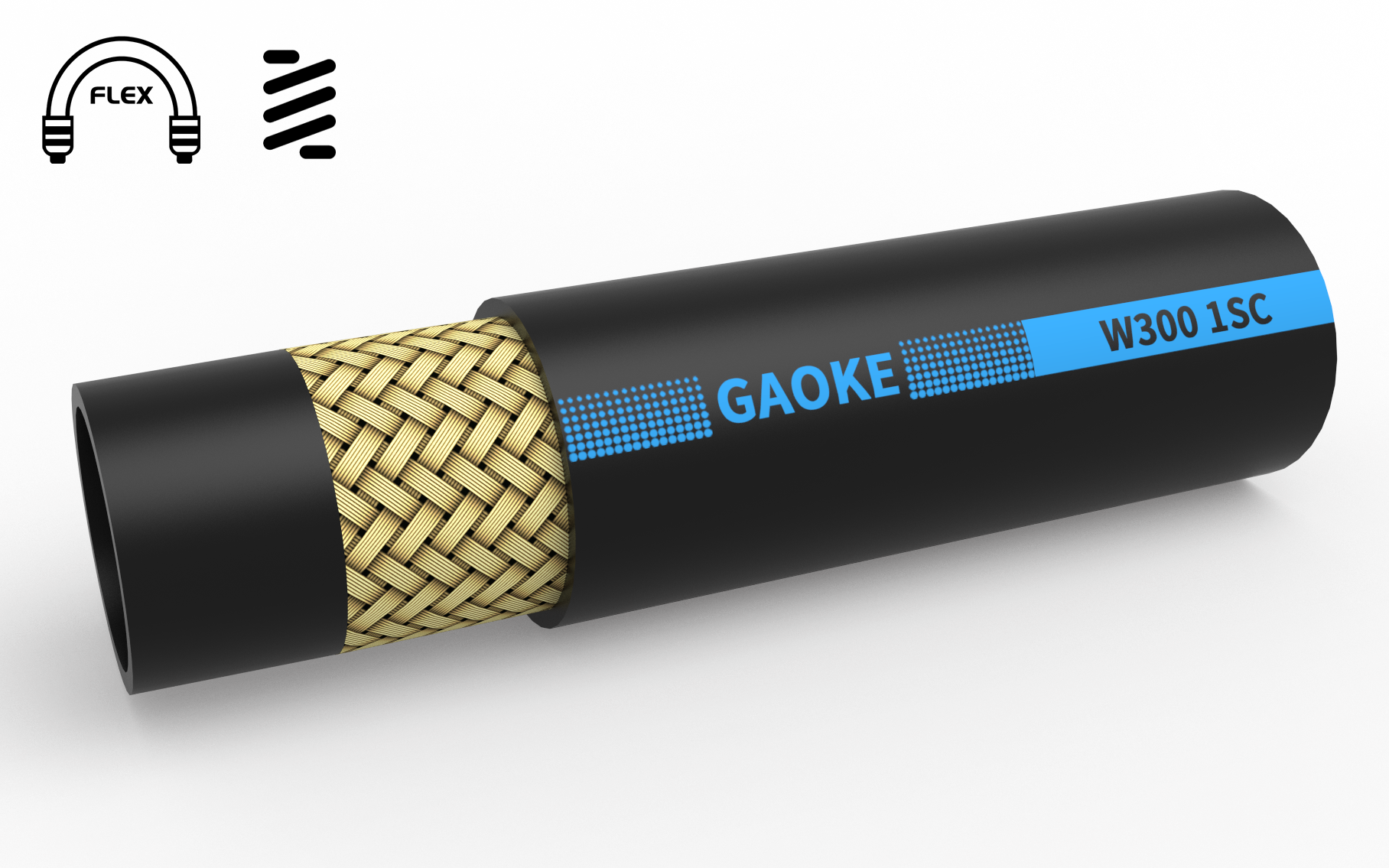

As industries continue to modernize and demand higher-performance equipment, the steel wire braided hydraulic hose has emerged as a critical component across multiple sectors including construction, mining, agriculture, and manufacturing. Known for its strength, flexibility, and ability to handle high-pressure applications, this type of hose plays a vital role in transferring hydraulic fluids within complex machinery.

Common Issues with Steel Wire Braided Hydraulic Hoses

Despite their durability, steel wire braided hydraulic hoses are not without challenges. Industry professionals frequently report the following issues:

1. Abrasion Damage

External wear due to rubbing against machinery or surfaces is a

leading cause of hose failure.

2. Improper Installation

Incorrect routing or excessive bending can shorten hose life and

lead to pressure leaks.

3. Bursting Under Pressure

When hoses are used beyond their rated pressure capacity, the risk

of sudden rupture increases.

4. Corrosion of Braided Steel Wires

In humid or corrosive environments, the steel braiding can rust,

compromising hose integrity.

5. hermal Degradation

Excessive heat can break down the inner tube, causing leakage

and system inefficiency.

Application Scenarios

Steel wire braided hydraulic hoses are commonly used in:

Excavators and Loaders

These machines require robust hoses to manage hydraulic

cylinders for lifting and movement.

Agricultural Sprayers

Hoses must withstand both pressure and chemical exposure in

crop spraying systems.

Industrial Press Machines

High-pressure hydraulic hoses control the motion and force in

press operations.

Drilling Equipment

In mining and oil industries, these hoses are exposed to extreme

pressure and vibrations.

Summary and Recommendations

As the demand for high-efficiency systems rises, the steel wire braided hydraulic hose remains indispensable. However, to ensure safe and effective operation, regular inspection, proper installation, and selecting hoses that match the application’s pressure and temperature requirements are essential.

By understanding common problems and adhering to best practices, users can extend the lifespan of their steel wire braided hydraulic hoses and maintain system reliability. Investing in quality hoses and trained technicians can prevent costly downtimes and safety hazards in high-pressure environments.

In conclusion, the steel wire braided hydraulic hose is a cornerstone of hydraulic systems, and awareness of its usage and maintenance is crucial for operational success.

steel wire braided hydraulic hose

Hydraulic Hoses For Construction Machinery

2025-07-04