01

2025

-

08

High Temperature Resistant Hydraulic Hose: Ensuring Safety and Efficiency Across Heavy Industries

In the evolving landscape of industrial operations, high temperature resistant hydraulic hoses have become indispensable components across various sectors, including the construction machinery industry, agricultural machinery, metallurgical operations, coal mining, rail transportation, and petroleum machinery. These hoses, engineered to perform under extreme thermal conditions, are key to maintaining system reliability, operational safety, and equipment longevity.

Broad Industrial Applications

In the construction machinery industry, where hydraulic excavators, bulldozers, and loaders operate in demanding environments, high temperature resistant hoses are vital. Engines and hydraulic systems can reach temperatures above 100°C. A standard hose might degrade quickly, but specialized hoses with oil-resistant synthetic rubber inner tubes and heat-resistant outer covers continue to perform without cracking or bursting.

Agricultural machinery such as harvesters and irrigation pumps often work under high solar radiation and long operation hours. In these applications, temperature-resistant hoses protect the hydraulic systems from heat-related failures, especially when equipment is used in southern climates or during summer harvests.

The metallurgical industry requires hoses that can endure even harsher conditions. Hydraulic presses, smelters, and rolling machines generate intense heat and operate continuously. Hoses in these systems must resist not just high temperatures but also exposure to metal particles, slag, and corrosive fluids. Failure in this environment can result in severe downtime and safety risks.

In coal mining, reliability is non-negotiable. Underground equipment like shearers and hydraulic props experience both high pressures and elevated temperatures due to friction and depth-related thermal gradients. A rupture or degradation of a hose in such a scenario can lead to environmental hazards or worker injuries.

Rail transportation systems—especially high-speed trains and locomotives—use hydraulic hoses in braking systems and transmission mechanisms. With components located near engines or other heat-emitting parts, only high temperature resistant hoses can ensure continued, safe function under varying seasonal and operational thermal loads.

In petroleum machinery, from drilling rigs to offshore platforms, hydraulic hoses are exposed to extreme temperatures and chemically aggressive media. A specialized hose with high-tensile steel reinforcement and synthetic rubber coating can maintain performance even at 135°C or more, ensuring stability and preventing leaks.

Common Issues and Technical Considerations

Despite their robustness, high temperature resistant hydraulic hoses face several challenges in industrial settings:

Thermal aging and cracking: Long-term exposure to heat can cause the hose’s cover and inner tube to harden and crack, especially if not rated correctly.

Delamination and blistering: Incompatible fluid or temperature overload can cause separation between hose layers, reducing pressure resistance.

Abrasion and external damage: Even high-temperature covers can degrade if subjected to constant friction or UV exposure.

Improper installation: Bending the hose below the recommended radius or exposing it to torsion can accelerate failure, even if it is thermally compatible.

To mitigate these risks, users are advised to:

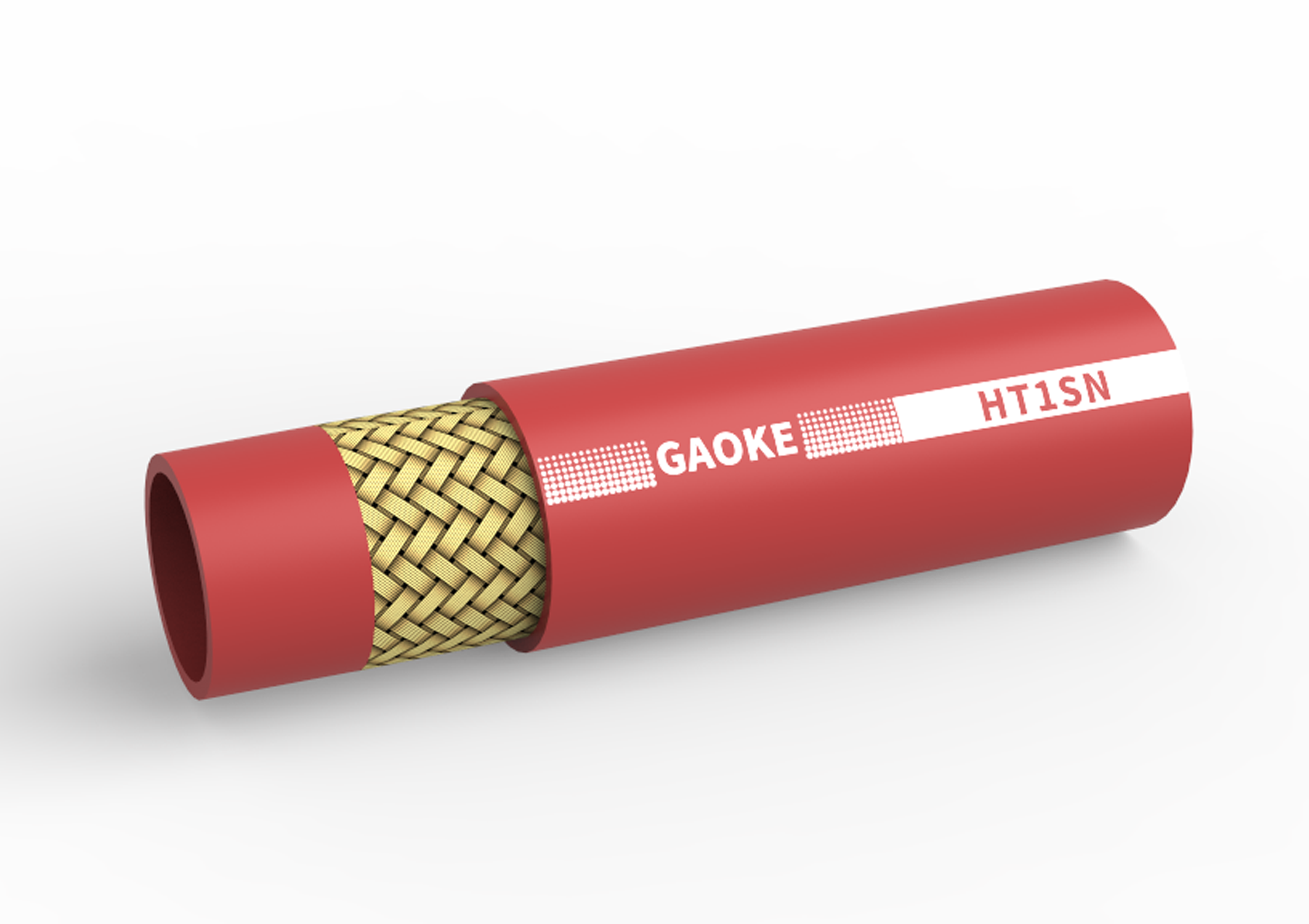

Select hoses that comply with international standards such as EN853 1SN or SAE 100R1AT.

Ensure compatibility with the specific media (e.g., mineral oil, water-glycol, synthetic lubricants).

Install protective sleeves or routing supports where needed.

Replace hoses at recommended service intervals or when early signs of fatigue appear.

Conclusion

The demand for high temperature resistant hydraulic hoses continues to grow with the expansion of high-load, high-heat industrial machinery. From the roaring furnaces of metallurgy to the rugged depths of mining, these hoses are the silent protectors of productivity and safety. As industries evolve, continuous innovation in hose materials, structure, and performance standards will be essential to meet tomorrow’s thermal challenges.

high temperature resistant hydraulic hose