04

2025

-

09

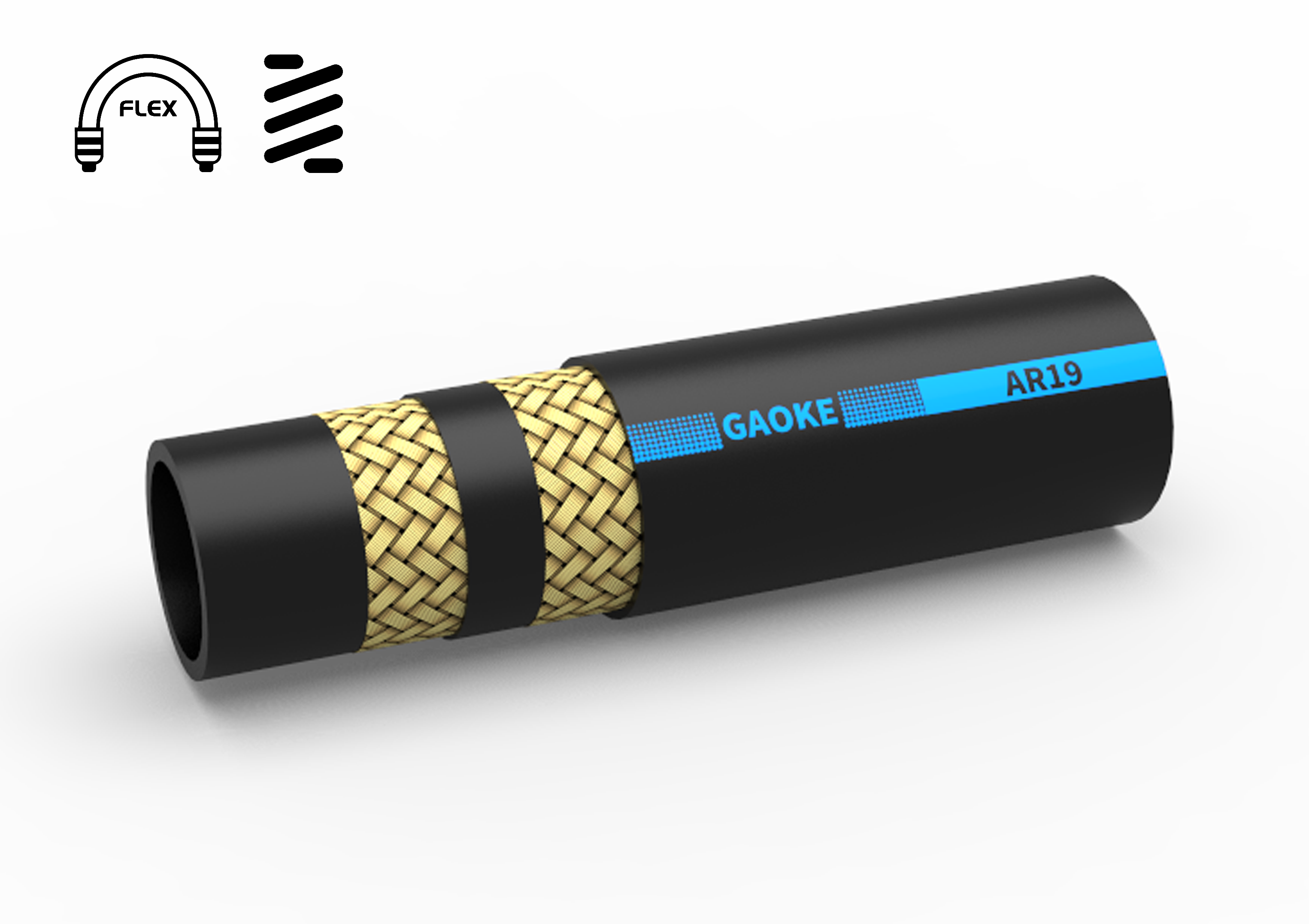

Compact Flexible Hydraulic Hose Enables Tighter Routing in High-Demand Hydraulic Systems

In environments where every millimeter counts, the advent of a compact flexible hydraulic hose enables installations that were previously impractical. These hoses, such as the SAE 100R19 “Compact Constant Pressure” model, maintain a uniform 28 MPa working pressure across all diameters—with a significantly reduced bend radius compared to traditional EN 853 2SN hoses—simplifying hydraulic system layout and reducing inventory complexity.

Technical Functionality

Two high-tensile steel wire braids provide structural reinforcement, allowing the hose to withstand high pressure while retaining a compact, ultra-flexible form. This allows installation within constrained assemblies—such as mobile machinery, industrial robots, or hydraulic tools—where dynamic movement and limited routing space are common.

A robust synthetic rubber inner tube ensures compatibility with mineral, synthetic, and biodegradable fluids, while resisting oil and heat. The outer cover is formulated to resist abrasion, ozone, and weathering—extending the hose’s lifespan in both indoor and harsh outdoor conditions.

Industry Applications

Gaoke Rubber cites a wide array of sectors where compact flexible hydraulic hoses play a role, including:

Construction, Agricultural, and Metallurgical Machinery — where installation space is restricted and machinery undergoes frequent movement .

Petroleum Machinery — connecting hydraulic power units to top drives, mud pumps, or derrick systems; these hoses must endure extreme pressures (35–70 MPa), vibration, and harsh conditions—especially in drilling rigs or cementing equipment.

Rail Transportation — used in braking systems, suspension, door mechanisms, and track-maintenance machinery. These hoses must support high pressures (20–40 MPa) and repetitive flexing, plus resist abrasion and environmental stressors.

Design Impact

Simplified Inventory & Design: Constant working pressure across sizes enables engineers to standardize hoses, reducing part diversity and simplifying hydraulic layout.

Installation Efficiency: Ultra-flexible design eases routing through tight paths, lowers installation time, and minimizes stress at fittings.

Durability in Challenging Conditions: Abrasion and weather resistance make these hoses suitable for mobile and outdoor applications where wear is a concern.

Conclusion

Advancements exemplified by compact flexible hoses like the SAE 100R19 model reflect a shift toward hydraulic components that support increasingly compact, mobile, and demanding environments. By combining constant pressure performance, refined flexibility, and environmental endurance, these hoses enable more streamlined system architectures without compromising reliability.

compact flexible hydraulic hose