22

2025

-

08

Reinforced Hydraulic Hose: Reliability and Challenges in Modern Industries

The Reinforced Hydraulic Hose has become an essential component in sectors ranging from construction and mining to agriculture and transportation. Known for its ability to withstand high pressure and provide reliable fluid power transmission, this hose plays a vital role in ensuring efficiency and safety across hydraulic systems. As demand for heavy-duty machinery continues to grow, the reinforced hydraulic hose market is expanding rapidly, supported by its performance advantages and continuous technological improvements.

Common Issues with Reinforced Hydraulic Hose

Despite its widespread use, the Reinforced Hydraulic Hose is not without challenges. The most common issues faced by industries include:

1.Abrasion and External Damage

Even though reinforced layers provide durability, hoses often operate in harsh environments where friction, debris, or sharp surfaces can cause wear, leading to premature failure.

2.Leakage and Pressure Loss

Improper installation, excessive bending, or prolonged operation under extreme pressure can lead to leakage at joints or cracks in the hose structure, reducing efficiency and increasing safety risks.

3.Temperature Fluctuations

Hydraulic systems often encounter high temperatures. Continuous exposure can degrade the hose’s internal structure, while extreme cold can cause rigidity and cracking.

4.Compatibility with Fluids

Not all hydraulic hoses are compatible with every fluid type. Using the wrong hose for specific oils or chemicals may accelerate degradation, impacting performance and safety.

5.Maintenance Neglect

One of the most frequent causes of hose failure is lack of regular inspection. Without timely maintenance, minor damages escalate into system breakdowns, resulting in downtime and costly repairs.

Application Scenarios

The Reinforced Hydraulic Hose finds extensive application in:

Construction Machinery: Excavators, bulldozers, and loaders rely on hydraulic hoses for smooth and powerful operation.

Agricultural Equipment: Tractors, harvesters, and sprayers depend on hydraulic systems for efficient farming operations.

Mining Industry: Heavy mining trucks and drilling rigs use reinforced hoses to handle extreme conditions with high pressure and dust exposure.

Oil and Gas Sector: Hydraulic hoses play a critical role in rigs, pumps, and drilling systems, where reliability is paramount.

Transportation: Buses, trucks, and rail systems utilize reinforced hoses for braking, lifting, and other hydraulic-powered functions.

Industry Response and Technological Advancements

To address the challenges, manufacturers are introducing hoses with multi-layer steel wire reinforcement, improved abrasion-resistant covers, and advanced rubber compounds that withstand higher temperature ranges. Additionally, smart monitoring technologies are being developed, enabling predictive maintenance through sensors that detect wear, pressure fluctuations, and potential leakage before failure occurs.

Conclusion

The Reinforced Hydraulic Hose remains a cornerstone of modern hydraulic systems, supporting critical industries worldwide. While common issues such as abrasion, leakage, and temperature effects cannot be entirely eliminated, advancements in material science and monitoring systems are significantly enhancing reliability. With proper maintenance and selection of the right hose type for specific applications, enterprises can maximize efficiency, reduce downtime, and ensure operational safety.

As industries continue to push for higher productivity and sustainability, the role of reinforced hydraulic hoses will only become more prominent. Investing in high-quality hoses and regular inspection is not just a technical requirement—it is a guarantee of long-term performance and safety.

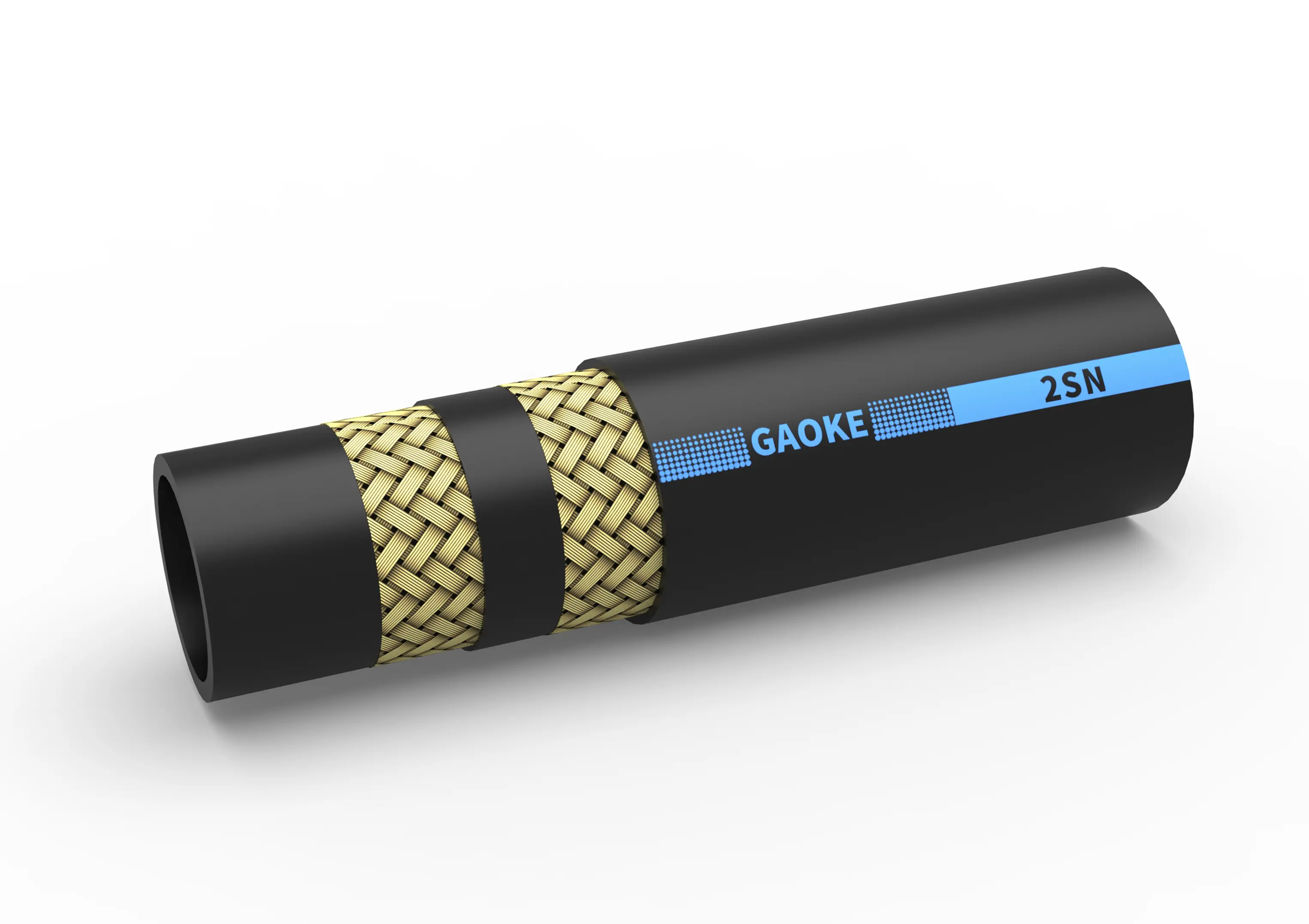

Reinforced Hydraulic Hose