14

2025

-

08

Innovative Metallurgy Hydraulic Hose Solutions Revolutionize Industry Performance

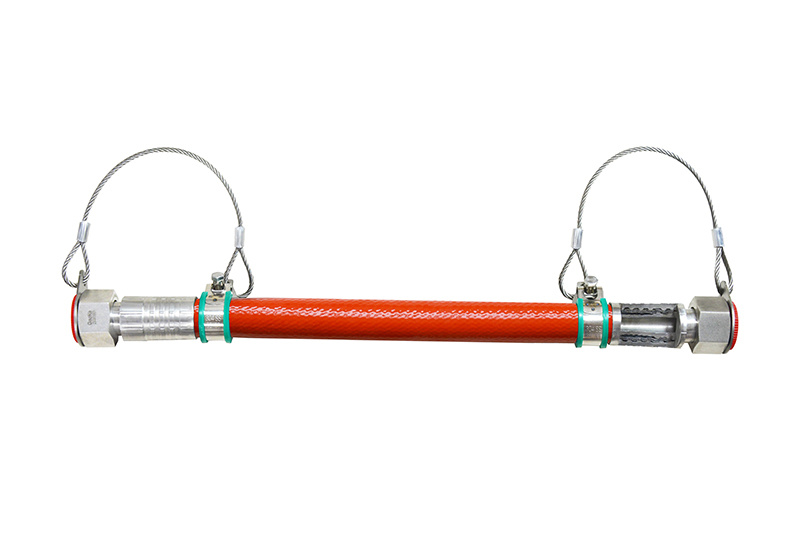

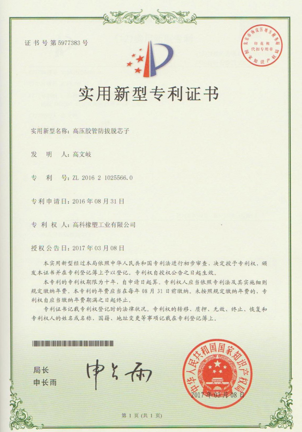

Gaoke’s Patented Triple-Proof Hose Assembly Sets New Standards in Extreme Conditions

In the demanding environments of metallurgy and coal mining, hydraulic hose failures can lead to costly downtime and safety hazards. Addressing these challenges, Gaoke’s patented Triple-Proof Hose Assembly has emerged as a game-changer, offering unparalleled durability and performance under extreme temperatures and pressures.

Cutting-Edge Specifications for Harsh Environments

Designed to withstand the most rigorous industrial conditions, Gaoke’s hose assembly boasts:

- Operating Temperature Range: -40°C to +150°C (up to 200°F), with fire-resistant variants capable of enduring short-term exposure to 600°C.

- Operating Pressure: 5MPa to 42MPa, ensuring reliability in high-pressure hydraulic systems.

- Materials: Constructed with Nitrile Rubber (NBR) for oil resistance and Fluororubber (FKM) for superior heat and chemical resistance.

These specifications make the hose ideal for metallurgical plants, steel mills, and coal mining operations, where conventional hoses often fail prematurely.

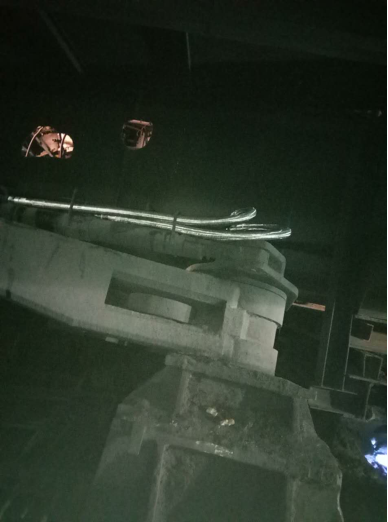

Proven Success in Extreme Metallurgical Applications

A standout case is the deployment of Gaoke hoses at Xuanhua Iron and Steel, where the hoses are installed near blast furnaces—an area with an average ambient temperature of 200°C and spikes exceeding 600°C during molten iron tapping.

Before switching to Gaoke, the plant faced frequent hose failures, requiring replacements every 0-7 days. However, after adopting Gaoke’s fire-resistant and anti-pullout hose assemblies, the replacement cycle extended dramatically to 30-45 days, reducing maintenance costs and improving operational efficiency.

Industry-Wide Adoption: Replacing Imported Alternatives

Traditionally, Chinese steel mills relied on high-end imported hoses, which come with long lead times and high costs. Gaoke’s domestically produced hoses have successfully replaced these imports, offering comparable—if not superior—performance at a more competitive price.

Following successful trials at Tangshan Iron and Steel, other major players like Jinxi Iron and Steel and Jianlong Steel conducted benchmarking tests and transitioned to Gaoke’s solutions. The results have been transformative:

- Enhanced fire resistance prevents hose degradation near high-heat zones.

- Anti-pullout reinforcement ensures secure connections even under intense vibration.

- Cost savings due to reduced replacement frequency and lower procurement expenses.

Future Outlook: Expanding Applications in Heavy Industries

With metallurgical and mining industries increasingly prioritizing safety, efficiency, and cost control, Gaoke’s Triple-Proof Hose Assembly is poised for broader adoption. The company continues to innovate, exploring higher-temperature-resistant materials and smart monitoring systems to predict hose wear before failure occurs.

As more Chinese steel mills and global industrial players recognize the benefits of import substitution without compromising quality, Gaoke is positioning itself as a leader in high-performance hydraulic solutions for extreme environments.

Gaoke’s metallurgy hydraulic hoses represent a significant leap forward in industrial durability, offering longer service life, reduced downtime, and cost efficiency compared to traditional solutions. With proven success in some of the harshest working conditions, these hoses are redefining reliability in heavy industries worldwide.

metallurgy hydraulic hose