07

2025

-

08

Heavy-Duty Hydraulic Hose: A Critical Component Across Multiple Industries

The heavy-duty hydraulic hose is an indispensable part of modern industrial operations, ensuring the efficient transmission of high-pressure fluids in demanding environments. Widely used in construction, agriculture, metallurgy, coal mining, rail transportation, and petroleum machinery, these hoses face extreme conditions, leading to common challenges such as wear, leakage, and pressure loss. Below, we explore their applications and recurring issues across key industries.

1. Construction Machinery Industry

In construction equipment like excavators, cranes, and bulldozers, heavy-duty hydraulic hoses endure constant movement, high pressure, and abrasive conditions. Common problems include:

- Abrasion Damage: Frequent contact with rough surfaces leads to outer cover wear.

- Pressure Spikes: Sudden load changes cause bursts if hoses lack sufficient reinforcement.

- Flex Fatigue: Repeated bending near joints results in cracks.

Scenario: On a busy construction site, an excavator’s hydraulic hose fails due to abrasion from rubbing against rocks, halting operations. Using abrasion-resistant sleeves can mitigate this issue.

2. Agricultural Machinery

Tractors, harvesters, and irrigation systems rely on hydraulic hoses for precise fluid control. Challenges include:

- Chemical Corrosion: Exposure to fertilizers and pesticides degrades hose materials.

- Weathering: UV rays and temperature extremes cause cracking.

- Contamination: Dirt and debris enter systems due to improper sealing.

Scenario: A combine harvester’s hose leaks after prolonged pesticide exposure, requiring replacement with chemical-resistant variants.

3. Metallurgical Industry

In steel mills and foundries, hoses operate near extreme heat and molten metal. Key concerns:

- Heat Degradation: Standard rubber hoses fail under high temperatures.

- Spark Damage: Flames and sparks burn through covers.

- High-Pressure Failures: Hydraulic systems in rolling mills demand ultra-durable hoses.

Scenario: A steel plant’s hydraulic line bursts near a furnace, prompting a switch to flame-retardant, high-temperature hoses.

4. Coal Mining

Mining equipment faces harsh, dirty conditions. Common hose failures:

- Crushing and Pinching: Heavy machinery can compress hoses.

- Particle Contamination: Coal dust clogs fittings, causing leaks.

- Low-Temperature Brittleness: Subsurface cold makes hoses prone to cracking.

Scenario: A hydraulic roof support system in a mine fails due to a pinched hose, emphasizing the need for crush-resistant designs.

5. Rail Transportation

Trains and rail maintenance equipment use hydraulic hoses for braking and lifting systems. Issues include:

- Vibration Fatigue: Constant motion weakens hose structures.

- Oil Compatibility: Incompatible fluids swell or degrade inner tubes.

- Outdoor Exposure: Hoses must withstand rain, snow, and temperature swings.

Scenario: A freight train’s brake system malfunctions due to a vibration-induced hose crack, highlighting the need for reinforced, flexible hoses.

6. Petroleum Machinery

Oil rigs and refineries subject hoses to high-pressure, corrosive fluids. Problems involve:

- Chemical Erosion: Crude oil and solvents eat away at inner linings.

- High-Pressure Bursts: Pump systems require hoses with robust wire braiding.

- Fire Hazards: Flammable environments demand fireproof materials.

Scenario: A ruptured hose on an offshore rig causes hydraulic fluid leakage, risking fires. Solutions include oil-resistant, fire-rated hoses.

Heavy-duty hydraulic hoses are vital across industries but face unique challenges based on their operating environments. Selecting the right material—whether abrasion-resistant, chemical-proof, or high-temperature—ensures longevity and safety. Regular inspections and adherence to pressure ratings can prevent costly downtime, making these hoses a linchpin of industrial efficiency.

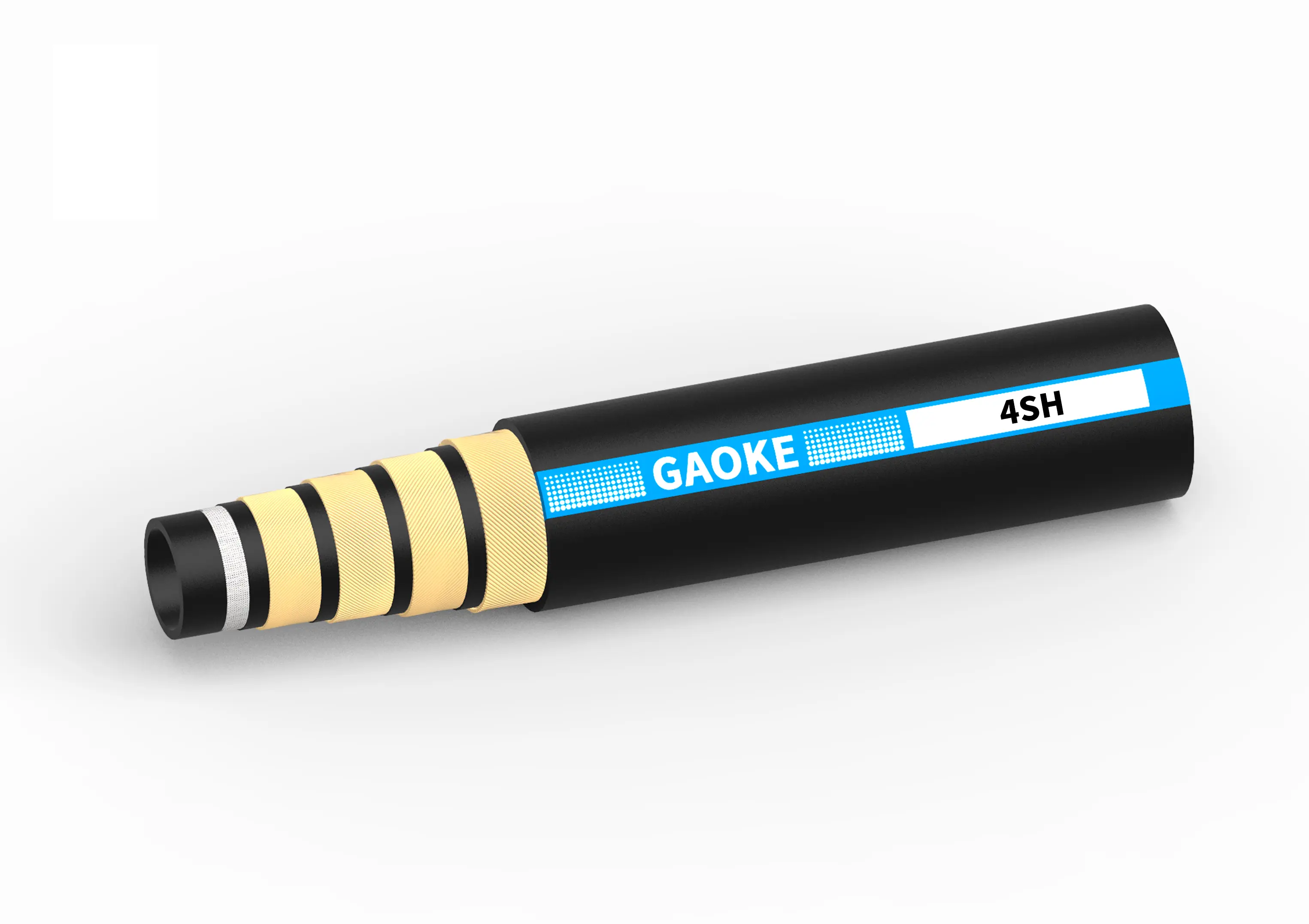

heavy-duty hydraulic hose